Fuel cell cars are known for their ability to use the commonly found hydrogen gas as fuel. When mixed with pure oxygen, it will generate electricity and the by-product is pure water. Hydrogen fuel cells are proven technology and they can be considered as truly green implementations; although it still depends whether the pure oxygen and hydrogen are acquired also with green techniques. Hydrogen is the lightest and simplest elements in the universe. It boils at -253 degrees Celsius and it can be stored at internal tank. When combines with oxygen, H2O will be formed and as we know, it is the chemical composition of pure water.

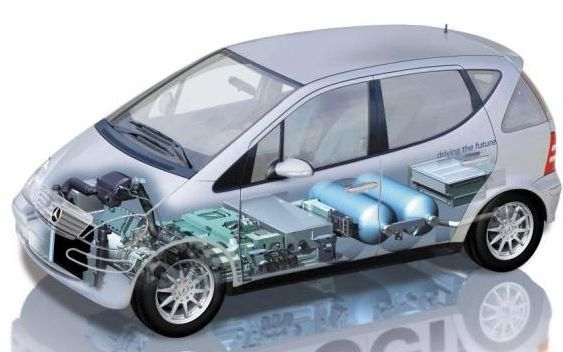

When oxygen and hydrogen combines; heat and electrical energy are generated. The electrical energy can be fed to the car’s drive motor. It should be noted that a single cell could produce barely one Volt, so a car requires a few hundreds of such cells which are stacked, so enough power can be used to proper the car. Nissan uses an auxiliary source of power, so the fuel cell stack can be supplemented when the car accelerates. The battery could also store energy recovered from the brake regeneration system. Nissan’s system is based on a co-axial motor that delivers 280Nm and 120PS.

Early electric cars could operate for 300 miles depending on energy usages and the maximum speed could reach 150km per hour. Efficiency and performance fuel cell cars continue to increase in recent years. In general, consumers look for cars that can provide them with reasonable driving range. In essence, hydrogen is a highly efficient source of energy with large energy density by mass. However, its energy density is poor by volume, so fuel cell cars require strong hydrogen tanks that can withstand high pressure. It means that the fuel cell could deliver a significant amount of energy.

Early hydrogen tanks could withstand only 35MPa, but newer cars could withstand about 70MPa. By increasing the pressure, it isn’t necessary to install larger tanks and this will surely make the car lighter. Hydrogen tank has internal aluminium liner, while the plastic reinforced carbon fiber is used on the outer layer. In general, we should make sure that the car uses high elasticity, high strength carbon fiber. It should also be noted that some issues could happen when the car operate in very cold condition. Fuel cells could work when they are humid inside.

When water is no longer found inside, it isn’t possible to sustain the electrochemical process. Then we should also consider that more water can’t be produced inside the cell to sustain the overall process. When we leave the car outside and expose it to the snowy winter night, water inside cells will freeze. As a result, the car will no longer be able to move. In some cases, this could cause permanent damages to the fuel cells. However, some car makers have come up with new solutions that allow the car started when the cell temperature is minus 30 degrees Celsius.